Electric vs. gas galley installations on boats

The All-Electric Galley: Is It Time to Ditch Propane on Your Boat?

For decades, the rhythmic hiss of a propane stove and the gentle clatter of a gimballed grate have been the quintessential soundtrack to a cruising boat’s galley. Propane has been a reliable, if sometimes fussy, partner for sailors cooking at sea. But a quiet revolution is taking place below decks, powered by advancements in battery technology and high-efficiency appliances. More and more boat owners are asking the question: Is it finally time to cut the gas line and embrace an all-electric galley?

The move from gas to electric is more than just a preference; it’s a fundamental shift in how we manage energy and safety onboard. It’s about trading the periodic anxiety of propane leak checks for the silent, efficient power of induction. This isn’t a simple appliance swap, however. It’s a holistic system upgrade that demands careful planning. Let’s weigh anchor and navigate the real-world considerations of making the switch.

The Case Against Propane: Why Sailors Are Reconsidering Gas

Before we dive into the allure of electric, it’s important to understand the push factors. Why are seasoned mariners, long accustomed to propane, looking for an alternative? The reasons generally fall into three categories: safety, convenience, and comfort.

The Unspoken Safety Concerns

Let’s be blunt: propane (LPG) is a heavy, highly flammable gas stored under pressure. On a boat, it demands respect and constant vigilance. A proper marine installation includes a dedicated, ABYC-compliant locker that vents overboard, a remote solenoid shut-off valve, and high-quality, chafe-protected lines. Even with a perfect system, the risk of a leak, however small, is always present. Since propane is heavier than air, any escaped gas will sink into the bilge, creating a potential explosion hazard just waiting for a spark. This inherent risk is the number one reason sailors dream of a gas-free boat.

The Convenience Conundrum

Anyone who has cruised internationally knows the frustration of sourcing propane. Bottle fittings and standards vary wildly from country to country, leading to a collection of questionable adapters or the expensive task of acquiring new tanks. It’s a logistical headache that an all-electric system simply eliminates. Furthermore, that dedicated propane locker, while essential for safety, consumes valuable deck or cockpit space that could be repurposed for other gear.

The Heat and Humidity Issue

A often-overlooked byproduct of burning propane is water vapor. Every flame on your stove is releasing moisture directly into your cabin, adding to the ever-present battle against dampness and mildew. On a hot, tropical evening, the ambient heat radiating from a gas stove can also turn the salon into a sauna. An electric galley significantly reduces both of these comfort-killing factors.

The All-Electric Promise: What’s Driving the Change?

The dream of an all-electric galley isn’t new, but until recently, it was impractical for most cruising boats due to power limitations. Two key technological advancements have changed the game entirely.

Induction Cooking: The Heart of the Modern Galley

Induction cooktops are the star players in the electric galley. Unlike traditional electric resistance burners that glow red-hot, induction uses a magnetic field to directly heat the cookware itself. The benefits at sea are massive:

- Efficiency: Around 85-90% of the energy goes directly into the pot, compared to about 40-50% for gas. This means faster boiling times and less wasted energy.

- Safety: The cooktop surface stays relatively cool to the touch, drastically reducing the risk of burns. When you remove the pot, the heating stops instantly.

- Comfort: With almost no waste heat, the galley stays much cooler.

- Cleaning: A flat, smooth glass surface is infinitely easier to wipe down than a complex gas hob with grates and burners.

The Power Revolution: Lithium (LiFePO4) Batteries

Induction’s high efficiency is great, but it still requires a significant burst of power. This is where older battery technologies, like lead-acid, would falter. The real enabler of the all-electric galley is the rise of Lithium Iron Phosphate (LiFePO4) batteries. They possess the high energy density and, crucially, the high discharge rate capability to power an induction hob and a microwave without damaging the battery bank. They provide the deep, reliable power reservoir needed to make electric cooking a daily reality, not just an occasional luxury when plugged into shore power.

The Reality Check: Planning Your All-Electric Conversion

Tearing out the gas lines is tempting, but a successful conversion requires a systems-based approach. Simply installing an induction cooktop without upgrading the infrastructure is a recipe for frustration.

Step 1: Conduct a Thorough Energy Audit

You cannot guess at your power needs. You must calculate them. An all-electric galley is a power-hungry beast. Start by estimating your cooking usage. A 1500-watt induction burner running for 20 minutes to boil water and cook pasta consumes 500 watt-hours. At 12 volts, that’s roughly 42 amp-hours (Ah) from your battery bank. Do that three times a day, add in a microwave, and you can see how quickly the consumption adds up. For most cruising couples, a LiFePO4 bank of 400Ah is a realistic minimum, with 600-800Ah being a more comfortable target for serious cooking.

Step 2: Plan Your Charging Strategy

A huge battery bank is useless if you can’t refill it. Your charging system must be able to keep up with your new, higher demand. This usually means a multi-pronged approach:

- Solar: This will be your primary workhorse at anchor. A significant array of 400-800 watts or more, managed by a quality MPPT charge controller, is essential.

- Alternator: When motoring, a high-output alternator (120A+) paired with an external regulator that is optimized for lithium charging is key to replenishing the bank quickly.

- Generator/Shore Power: For extended periods of bad weather or heavy usage, a small generator or the ability to plug into shore power provides a necessary backup.

Step 3: Choose the Right Appliances

With power sorted, you can select your hardware. You’ll need more than just a cooktop.

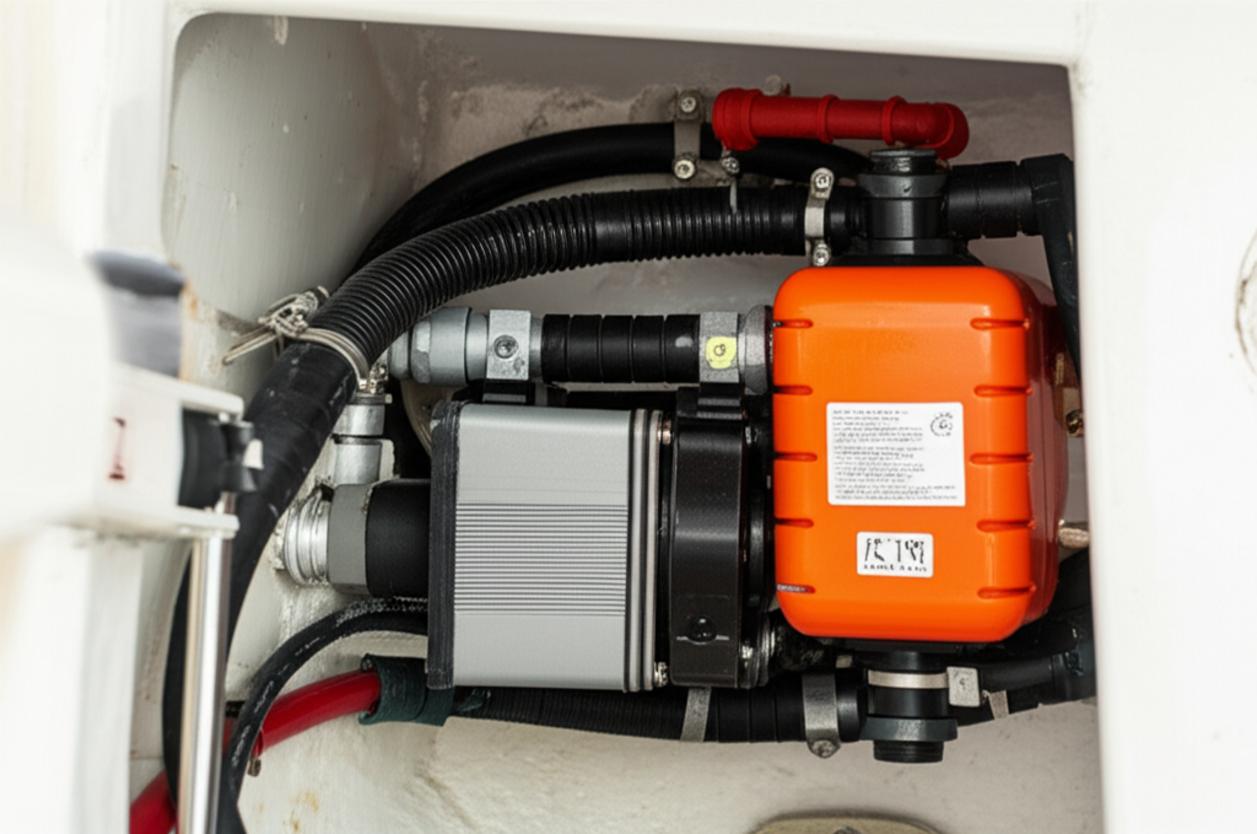

- Inverter: A high-output, pure sine wave inverter is non-negotiable. This device converts your 12V DC battery power to 120V/230V AC for your appliances. A 2000-watt unit is a bare minimum, but a 3000-watt inverter/charger is a more robust choice that can handle multiple loads.

- Cooktop: Choose a marine-grade or high-quality residential single or double-burner induction unit. Pay attention to its maximum wattage to ensure your inverter can handle it.

- Other Appliances: A combination microwave/convection oven is a popular, space-efficient choice to replace a traditional gas oven. Electric kettles and toaster ovens also become viable options.

Conclusion: Is the Future of Your Galley Electric?

Making the switch to an all-electric galley is a significant undertaking, both technically and financially. The upfront cost of a substantial LiFePO4 battery bank, a large inverter, solar panels, and new appliances is considerable. It is not a weekend project.

However, the rewards are equally significant. The payoff comes in the form of enhanced safety by removing a volatile gas from your living space, unparalleled convenience with a single fuel source for all your systems, and a cleaner, cooler, and more comfortable cooking environment. For the modern cruiser investing in a robust electrical system, the all-electric galley is no longer a futuristic concept—it’s a logical, safer, and ultimately more enjoyable evolution of life at sea.