There are few sounds on a boat as simultaneously mundane and crucial as the hum of the freshwater pump. It’s the sound of a morning coffee brewing, a refreshing rinse after a swim, and a clean galley after a hearty meal. But when that familiar hum turns into a constant drone, a frantic pulsing, or worst of all, a dead silence, your tranquil life at sea can quickly become a frustrating ordeal.

Your boat’s pressurized water system is its circulatory system, and the pump is its heart. While they are designed to be robust, they don’t last forever. The good news is that replacing a freshwater pump is one of the most manageable and rewarding DIY projects a boat owner can tackle. It requires a few basic tools, a bit of patience, and will leave you with a deeper understanding of a critical onboard system. Let’s dive in.

Is It Really the Pump? Diagnosing the Problem

Before you rush to buy a new pump, let’s play detective. Many pump-like symptoms are actually caused by other issues in the system. A proper diagnosis will save you time and money.

* The pump runs continuously and never shuts off: This is the classic sign of a leak. The pump is trying to build pressure, but water is escaping somewhere, so it never reaches the cut-off pressure. Before blaming the pump, check every single connection in your freshwater system: faucets, showerheads, hot water heater connections, and the hose fittings themselves. Even a tiny, slow drip is enough to keep the pump running.

* The pump cycles on and off quickly (machine-gunning): If you hear a rapid brrr-brrr-brrr sound when you crack open a faucet just a little, this often points to a failed or waterlogged accumulator tank. The accumulator tank acts as a pressure buffer, smoothing out the water flow. If its internal bladder has failed, the pump will short-cycle. It can also be a sign of a clogged inline filter, which restricts flow and confuses the pressure switch.

* The pump is completely dead: The simplest explanation is often the correct one. First, check the dedicated circuit breaker or fuse for the pump. If it’s tripped, reset it once. If it trips again immediately, you have an electrical short. If the breaker is fine, use a multimeter to check if you have 12V (or 24V) power at the pump’s terminals. If you have power but the pump does nothing, the motor is likely seized or burned out. It’s time for a replacement.

* Low water pressure throughout the boat: The number one suspect here is a clogged filter or strainer. Most pumps have a small, screw-on strainer on the inlet side to protect the diaphragm from debris. These can get clogged with sediment from your water tank. Cleaning this filter should be your first step.

Choosing Your New Pump: More Than Just Flow Rate

If you’ve confirmed the old pump is the culprit, it’s time to choose a successor. You could get an identical replacement, but this is also an opportunity to upgrade.

* Flow Rate (Gallons Per Minute – GPM): This determines how much water comes out of your tap. A 3-4 GPM pump is usually sufficient for a mid-sized boat with a couple of faucets and a shower. A direct replacement is safe, but a small upgrade in GPM can be a nice improvement. Don’t go overboard, as your boat’s plumbing and wiring might not be sized for a massive pump.

* Pressure (PSI): Most marine systems operate between 30-50 PSI. The key is the pump’s pressure switch, which has a cut-in (when it turns on) and cut-out (when it shuts off) pressure. Match this to your system’s specifications. A pump with too high a PSI could damage your plumbing or hot water heater.

* Voltage: This is non-negotiable. If you have a 12V system, you need a 12V pump. If you have a 24V system, you need a 24V pump.

* Variable Speed vs. Standard: This is the biggest upgrade you can make. A standard pump is either on (full blast) or off. It relies on an accumulator tank to smooth out the flow. A modern variable-speed pump intelligently adjusts its motor speed based on demand. When you open a faucet slightly, it runs slowly; open it fully, and it speeds up. The result is a quiet, smooth, household-like water flow, and it often eliminates the need for an accumulator tank, saving space and a potential failure point.

The Toolkit: Assembling Your Arsenal

You don’t need a professional workshop for this job. Gather these items before you start:

* The new water pump

* Screwdrivers (Phillips and flathead)

* Pliers or a wrench for hose clamps

* Wire strippers and crimpers

* Marine-grade, heat-shrink butt connectors

* Pipe sealant or Teflon tape for threaded fittings

* A handful of rags and a small bucket for catching water

* A camera (your phone) for taking ‘before’ pictures

Step-by-Step: The Replacement Process

With your tools and new pump at the ready, it’s time for the transplant.

1. Safety First: Go to your electrical panel and switch off the circuit breaker for the freshwater pump. You don’t want it to kick on unexpectedly while you’re working.

2. Depressurize the System: Open any faucet on the boat to bleed off all the pressure in the lines. Leave it open.

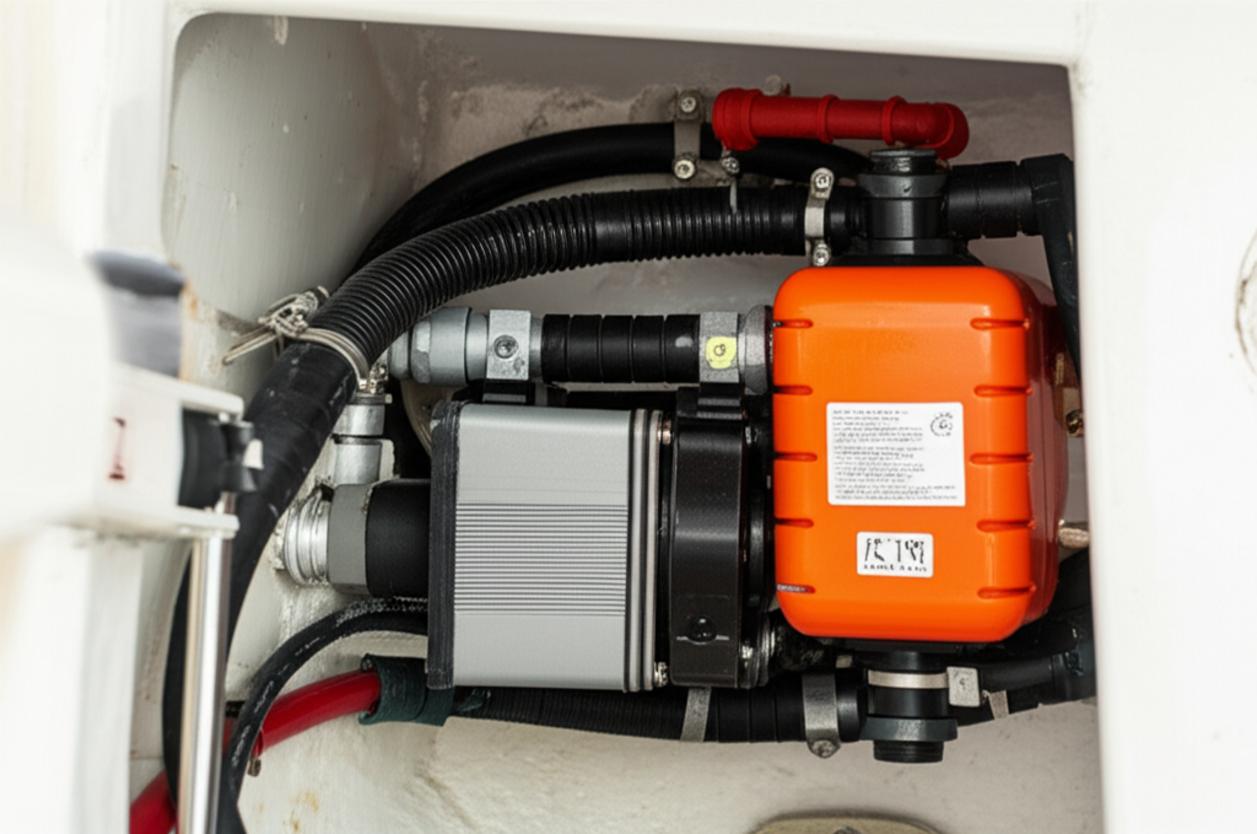

3. Locate and Photograph: Find your old pump. It’s often tucked away in an engine room, a lazarette, or under a settee. Before you disconnect a single thing, take a few clear photos from different angles. This will be your map for connecting the new one, especially for wire polarity and hose direction (inlet vs. outlet).

4. Disconnect the Plumbing: Place a rag or shallow bucket under the pump. Loosen the hose clamps on the inlet and outlet hoses and wiggle them off the pump fittings. Be prepared for a bit of residual water to spill out.

5. Disconnect the Wiring: Disconnect the positive (usually red) and negative (usually black) wires. If they aren’t color-coded, refer to your photo or label them with tape.

6. Unmount the Old Pump: The pump will be secured to a surface with screws through its rubber mounting feet. Unscrew these and remove the old pump from its lair.

7. Prepare the New Pump: Compare the new pump to the old one. You may need to transfer the threaded hose barb fittings. If so, clean the threads and apply fresh Teflon tape or pipe sealant before screwing them into the new pump. Make sure the inline strainer is attached to the inlet side—this is critical for the pump’s longevity.

8. Mount the New Pump: Position the new pump and screw it down. Ensure it’s secure, as the rubber feet are essential for isolating vibration and noise.

9. Reconnect the Wiring: Using your marine-grade butt connectors, crimp the boat’s positive wire to the pump’s positive wire, and negative to negative. Use a heat gun or a lighter carefully to shrink the tubing for a waterproof seal.

10. Reconnect the Plumbing: Push the inlet and outlet hoses firmly onto the new fittings and tighten the hose clamps. Ensure they are snug but don’t overtighten and crack the plastic fittings. Make sure the hoses aren’t kinked.

The Moment of Truth: Powering Up and Priming

Double-check that every connection is tight. Close the faucet you left open. Now, head back to the electrical panel and flip the breaker on. The pump should immediately start running as it works to build pressure in the empty lines.

Now, you need to purge the air. Go to the faucet furthest from the pump and open the cold tap. It will sputter and spit air for a moment before a smooth, steady stream emerges. Once the cold is clear, do the hot side. Repeat this process for every faucet, shower, and washdown on the boat.

Once all the air is out, close the last faucet. The pump should continue to run for a few seconds and then shut off with a satisfying click. Silence. Wait and listen. If the pump stays off, congratulations! If it cycles on for a second every 30 seconds or few minutes, you have a very small leak somewhere. Your new connections are the most likely suspects, so check them first.

Conclusion

Replacing your freshwater pump is more than just a repair; it’s an investment in your comfort and self-sufficiency on the water. By taking the time to diagnose the problem correctly, select the right replacement, and install it with care, you’ve not only solved an issue but also gained invaluable knowledge about your vessel. Now, go ahead and turn on that tap. The sound of that strong, steady stream of water, powered by the heart you just installed yourself, is one of the sweetest sounds a sailor can hear.